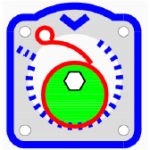

- US Patent 10006357 Full Cycle Rotary Engine Combination, (or see Google);

- US Patent 9638186 Rotary Pump and Rotary Motor, (also see Google );

- JAMES WATT’S THREE-VANE ROTARY OF 1782 will become true soon! 1v

https://rollingpiston.com/wp-content/uploads/2018/12/RRR3-c-1-1.gif

Conventional piston engines are heavy, complex and expensive, yet not efficient enough to meet the increasing energy-efficiency and emission requirements.

Other Rotary engine designs (e.g. Wankel, Mazda, and LiquidPiston) suffered several fatal PROBLEMS including:

- Significant friction wear caused by multiple pressurized sealing contacts moving on changing length and angle of its path. This structural problem cannot be solved with improvements in material, coating, or lubrication;

- Difficult dynamic sealing and excessive lubrication.

- Short, incomplete combustion mingled with exhaust resulting in poor performance and dirty emission.

All the above PROBLEMS STRUCTURALLY SOLVED by a totally different design. The principle is:

- providing efficient dynamic sealing,

- avoiding any sliding or rubbing friction under pressure,

- radial sliding movements transferred into rolling movements.

This new rotary engine features :

- minimal reciprocating mass,

- excellent radial dynamic sealing without harmful sliding friction,

- simple structure, very high power-to-weight ratio,

- avoided unneeded losses,

- better thermal efficiency,

- cooler emission,

- reduced cost of engine fabrication and maintenance by half, compared to modern engines.

http://rollingpiston.com/wp-content/uploads/2018/12/Next_02-2.mp4